About Strategic Initiatives

To meet our mission of delivering integrated research solutions, NRRI is focused on three strategic initiatives that address the challenges of Minnesota’s resource-based economy. These initiatives are bold and long-term efforts to create the economy of the future by incorporating diverse expertise across NRRI, the University system and with our partners.

Initiative Overview

NRRI's Iron and Minerals of the Future initiative focuses research to assist Minnesota’s evolving mineral industries to develop a robust and competitive portfolio of value-add iron and other mineral products. This requires new practices and technologies that increase efficiencies, reduce energy and water consumption and prevent environmental contamination.

Impact

After some 140 years of mining, the iron ore on the Mesabi Range is getting deeper and more expensive to mine. At the same time, energy costs are going up and markets are changing, along with concerns about environmental impacts. NRRI is helping Minnesota’s Iron Range prepare for changing mining practices and processes to meet the demands of changing ore bodies and develop a broader, iron-based product portfolio.

Goal

This Initiative is a collaborative effort to develop and introduce a portfolio of practices, processes, iron and non-ferrous products that require less energy and water while also reducing effluents. The goal is to provide research and development into areas that iron ore mining companies don’t have the resources to fully investigate and to reduce their risk in making changes.

Sample Projects

- Value-added byproduct use for road maintenance products

- Evaluate uses for iron mining waste piles

- New processing technologies for ore mixes of magnetite, goethite and hematite

- New processes for higher value Direct Reduced Grade (DRG) and Direct Reduced Iron (DRI) products for Electric Arc Furnace steel production

- Technical assistance for developing iron ore potential in long-term battery storage

Partners

- Minnesota’s Taconite Industries

- Supporting Industries

- Natural Resources Agency Partners

- Tribal Nations

- Iron Range Communities

Iron and Minerals of the Future Programs

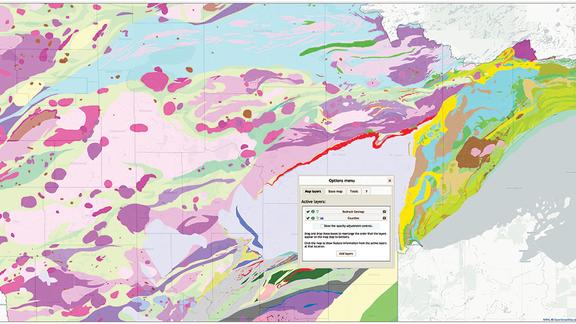

Researching regional materials that can be used for economic and/or industrial purposes. Economic Geology program is the center for economic geology studies and mineral resource characterization in the University of Minnesota system.

Defining mineral characterization through the spatial distribution of materials and mineral geologic properties and how that relates to extraction of commodity materials.

Continued investment in assets and capabilities to support regional mineral industry development.

Focusing on Minnesota’s ore bodies to understand the most optimal process for extracting metals for a variety of iron products.

Researching technologies to separate materials from our mineral resources with the least amount of waste or and environmental impact.

Developing next generation taconite pellets to help Minnesota's ore processing industry to prepare for the future.

Seeking to find beneficial use of mineral-based secondary products generated by mining and other industrial activities,

Iron and Minerals of the Future Projects

Online mapping tools and data for natural resource planning, management, and research in Minnesota.

Developing a durable road repair patch utilizing taconite tailings, the waste rock left over from the iron ore mines on Minnesota's Iron Range.

Recent News

NRRI tests waste rock as a safe and readily available high friction road aggregate.

Title: NRRI Researcher 3: Mineral Processing & Metallurgy Staff Scientist

Job ID: 361410

Location: Coleraine

Job Family: Research-Researchers

Full-Time/Regular

Pilot-scale, vertical mill from Switzerland is ‘game-changer’ for industry decarbonization efforts.

Job ID: 361004

Location: Coleraine, MN

Job Family: Campus Operations

Full-Time/Regular

Job Code: 8421HS

Employee Class: Civil Service