Minnesota has a challenging goal: Reduce sulfate levels to 10 parts per million (ppm) liters in water bodies with naturally occurring wild rice. For other waters, the drinking water standard for sulfate is 250 ppm.

Industrial processes, agricultural practices and power generation – as well as natural mineral weathering – all contribute to elevated sulfate. It’s a state-wide problem that’s difficult to address. In April this year, the U.S. EPA added 30 wild rice water bodies impaired with elevated sulfate to Minnesota’s Clean Water Act Impaired Waters List.

Difficult and Costly

Sulfate is an ion that dissolves in water which makes it especially difficult to remove. There are some effective remediation technologies on the market, but they are challenging for small municipalities and industries to implement. Reverse osmosis and membrane filters, often used to treat sulfate in water systems, are energy intensive and expensive to implement. Chemical precipitation, used to treat sulfate at levels of 1,000-plus ppm, produces a large amount of sludge that is a waste disposal problem.

NRRI is working with stakeholder partners to develop a portfolio of cost-effective sulfate reduction methods that work across these widely varying situations and standards.

Solution 1 for Municipalities

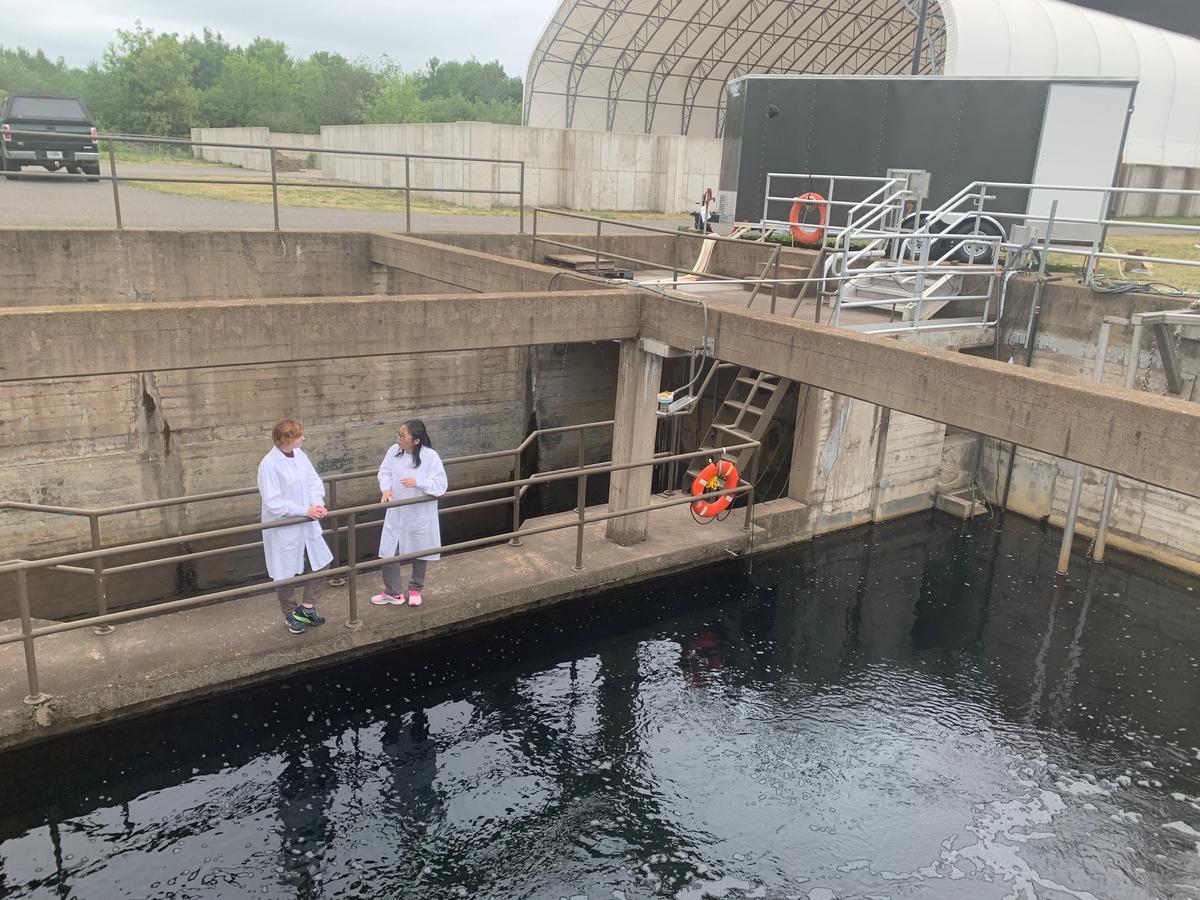

NRRI is testing onsite pilot trials of a unique chemical precipitation system at two wastewater treatment plants. In both cases, the system is meeting the 10 ppm sulfate reduction goal.

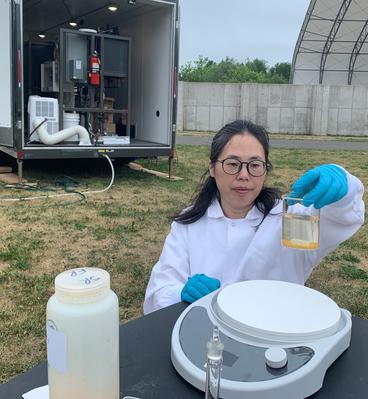

“We add a chemical to the water that reacts with the sulfate to produce solid particles,” explained project co-lead Mei Cai, NRRI environmental engineer. “The particles then form into a solid mass that can be removed from the water in a final filtration step.”

The system was first tested in the laboratory before being scaled up to a mobile, pilot-scale unit that was deployed this summer. Results show that sulfate in wastewater from two northern Minnesota towns was successfully reduced from approximately 80-100 ppm to 10 ppm or lower. NRRI engineers designed and directed the manufacturing of the unit, working with Intuitech, Inc.

“Operation costs are relatively low and the system is easily adapted for equipment in place at a plant or facility,” Cai added.

This applied research project is funded by the Legislative-Citizen Commission on Minnesota Resources.

Solution 2 for Industries

Reducing sulfate is a large cost burden for industry. Sulfate levels in industrial discharges range from a few hundreds to over 10,000 ppm. NRRI is also developing a sulfate reduction technology that employs microbes and regional mineral materials in a bioreactor. Similar to municipal treatment systems, water is pumped through this system for sulfate reduction.

“This biological treatment uses natural soil microorganisms’ ability to convert the sulfate ion to sulfide ion which is then immobilized by the minerals,” said Project Lead Chan Lan Chun, NRRI environmental engineer. “Once the sulfide is captured, it can be removed as a manageable solid phase.”

The goal is to scale up the process – potentially to full-scale – in a few years, demonstrating sulfate reduction for agriculture, industry and mine pit lakes. NRRI currently has a demonstration pilot unit deployed with project partner Minnesota Power to test the technology at one of their utility plants.

This project is funded by the University of Minnesota MnDRIVE program – Minnesota’s Discovery, Research, and Innovation Economy – to address the state’s grand challenges.

A biofiltration system is also in the planning stages for a pilot demonstration that targets extremely elevated groundwater resources or mine drainage situations.

Solution 3 Peat-based Ion Exchange

Another system NRRI is developing to target sulfate and other pollutants uses a granular material derived from peat that functions as an ion exchange resin. The goal is to attach the right groups of atoms to the peat surface that can selectively absorb and hold the sulfate ion.

“It’s complicated because each treatment technology has to be designed to encompass the background water chemistry,” explained NRRI Organic Chemist Igor Kolomitsyn.

He and his team have developed more than 200 natural peat derived anion exchange prototypes. They winnowed that down to 15 and are now testing those to find one prototype that removes the targeted pollutant. Kolomitsyn hopes to complete the bench-scale testing and have a viable sulfate removal candidate by the middle of 2023.

This effort is funded by a partnership with American Peat Technologies LLC in Aitkin, Minn. Funding for the bench-scale testing will be provided by the Legislative-Citizen Commission on Minnesota Resources.

Taking a Portfolio Approach

There are many ways excessive sulfate gets into lakes and groundwater, as well as many different levels of sulfate to contend with. This is why NRRI is developing a variety of solutions.

“It’s more of a market-pull approach,” said Chun. “Sulfate concentrations vary widely across the state from a variety of sources. But if we customize our approach, we can be most effective for each situation.”

The goal for all three projects is to make sulfate remediation achievable statewide to improve water quality and lower costs.