NRRI is hoping that one waste stream – excessive paper waste – can provide a solution for another pollution problem: single use plastic. And hopefully, make Minnesota the manufacturing and distribution hub for this new product.

Stadiums and airlines, in particular, are considering how to reduce the plastics in their food service. They need a biodegradable food tray that can be heated in an oven and that will also stand up to wet, greasy foods.

The Minnesota Pollution Control Agency is funding NRRI’s research to address this industry need through their Recycling Market Development program.

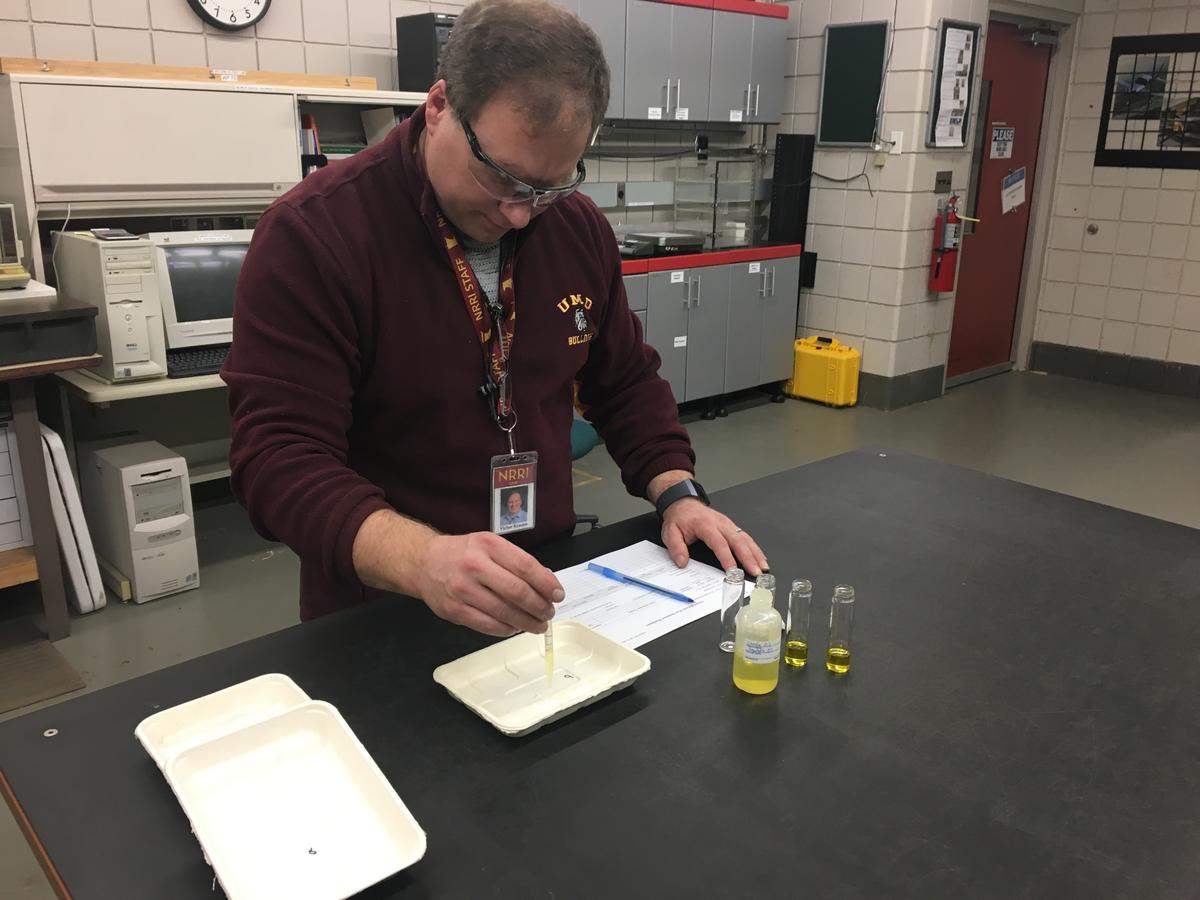

NRRI Bioeconomy Initiative Director Eric Singsaas is working to turn recycled paper pulp into biodegradable food trays that will hold up to a greasy chili cheese dog. Current “cardboard” products on the market are either leaky or they’re coated with plastic which keeps them from composting.

“Our dream would be that the tray and packaging and food are all compostable, going into one bin,” said Singsaas. “Stadiums and airports would have their own industrial compost stations on site.”

And he’s developing this off a product already being marketed. An inventor in Israel patented a heat and grease resistant, compostable food tray using sugar cane harvest byproduct. Joseph Siani, Founder of W-Cycle, is working with NRRI to develop the same product out of locally-sourced recycled paper, opening new markets for the pulp and reducing single use plastic pollution. Verso Corporation’s Duluth Paper Mill is supplying recycled pulp for product trials.

Once the product is developed, Siani hopes to set up a national manufacturing and distribution center for the products here in Minnesota. He already has a lot of traction for his sugar cane product in Europe and Australia.

“Our innovative patent is the first ever eco-friendly and compostable, single use packaging solution,” said Siani. “I have been researching this product since 2003 with the goal to make a material that is 100 percent compostable and can withstand temperatures from the oven to the freezer.”

Singsaas admits that reformulating the sugar cane product to recycled paper pulp is challenging, but societal demand is generating research funding to move this along.

A trial formulation was pressed into trays that are being sent to the Wisconsin Institute for Sustainable Technology at the University of Wisconsin, Stevens Point. There, a Compostability Certification Lab will test the product against the ASTM and Biocompostable Products Institute technical standards. The goal is to develop the trays with the maximum possible percent of recycled content.

“I’ve been trying to work in this area for a long time, but now people are making plastics into a high profile issue,” said Singsaas. “I feel like the world is finally catching up to what I’ve been wanting to do with my career.”