Rocks from all over the world are shipped to NRRI’s Minerals Laboratory in Coleraine. Mining companies want to know what’s in their materials so they know how to process them.

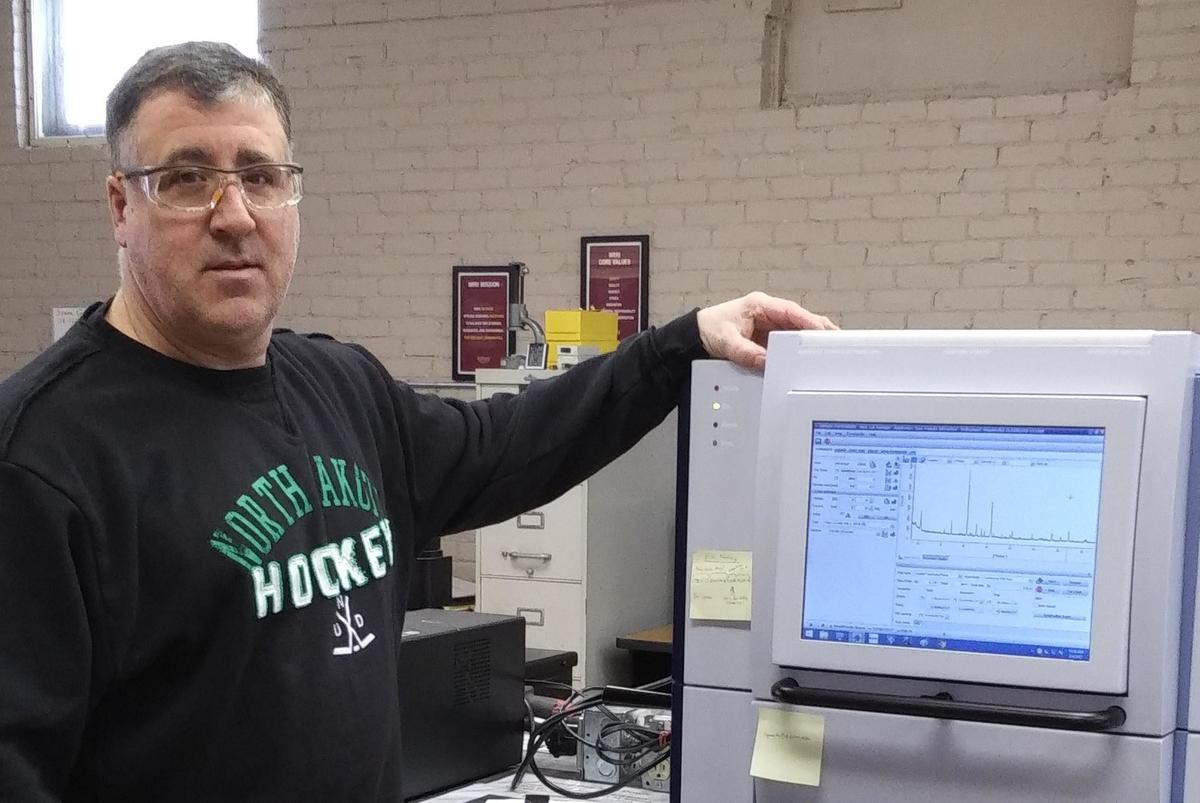

But before NRRI researchers get to work on the samples, they need to know if the rock is safe to handle. Greg Gargano is NRRI’s Iron Analysis Coordinator and Lab Technician for the new Minerals Safety Screening Program.

The first step is to stand 100 feet away and scan it with a hand unit (scintillometer) that checks for radiation.

“If it’s a sample we’ve never run before, we need to screen it for hazardous materials,” explained Gargano. “We don’t want to contaminate our labs with these hazardous materials which can become airborne once they are crushed.”

If there’s no radiation, the next step is to screen it for asbestos minerals using X-ray Diffraction (XRD). The sample is also checked for heavy metals, such as chromium or lead, using Energy Dispersive X-ray Fluorescence (XRF).

Gargano was trained to use the XRD instrument to do the initial asbestos screening, and the EDXRF instrument that identifies the chemical signature of these unknown samples. The EDXRF wasn’t completely new to Gargano. Prior to coming to NRRI in 2007 he worked at Cleveland Cliffs, in which he worked with the company’s EDXRF in their lab.

“But back then, it was a huge unit,” he laughed. “Now we have a desktop model. So I had to get comfortable with the new tools.”

Gargano generates raw data from the samples and sends it to NRRI Senior Research Geologist Steve Monson Geerts to identify the content.

Gargano is also kept busy with NRRI’s Iron of the Future project, funded by the Legislative-Citizen Commission for Minnesota Resources (LCCMR). Rock samples come in from all over the Iron Range that he crushes and binds with epoxy into mounts that are polished for microscope analysis by NRRI geologists in Duluth.

“In July we started working on a new calibration curve on the EDXRF Instrument for the LCCMR project samples,” said Gargano. “The researchers need to know the concentration of silica, iron, calcium and aluminum and with the new calibration, we’ll be able to process them faster.”

LCCMR is the Legislative-Citizens Commission for Minnesota Resources that is funding the Iron of the Future project.

Pandemic Paperwork

The lock-down in March and through the summer afforded time to document processes, which kept Gargano busy at home. Now, with all the samples that need processing, he’s in the lab three to five days a week.

He worked with NRRI Quality Manager Lisa Estepp to write the lab procedures. “Whatever paperwork needed to get done, that was a nice break to concentrate on that,” said Gargano.